In this article, we will be investigating the cutting-edge materials and ingenious structures that drive the future of flight and the aerospace sector. From lightweight composites to high-temperature alloys, join us as we unveil the secrets behind the remarkable advancements shaping the aerospace landscape.

The Aerospace Industry: A Historical Perspective

The aerospace industry has a rich history deeply intertwined with the evolution of materials and structures. At its inception, traditional materials like aluminium and steel played pivotal roles in aviation history. Aluminium’s lightweight nature and corrosion resistance revolutionised aircraft design, while steel provided the necessary strength for larger aircraft and critical components. Over the decades, aerospace companies have continuously adapted to new materials and technologies, driving the industry’s evolution.

A Leap Forward with Emerging Technologies and Advanced Materials

Our focus quickly shifts to advanced materials that have taken aerospace engineering to new heights. Carbon fibre composites, titanium alloys, and ceramics have propelled the industry forward. Carbon fibre composites, made by embedding carbon fibres in a polymer matrix, offer exceptional strength and lightweight properties, enhancing fuel efficiency and performance. Titanium alloys, renowned for their high strength and corrosion resistance, are essential in critical components like engines and airframes. Ceramics excel in high temperature and harsh conditions, which is vital for aerospace applications requiring extreme heat resistance. Aerospace manufacturers play a crucial role in integrating these advanced materials into aircraft design, enhancing performance and efficiency.

High-temperature superalloys

These are critical in aerospace innovation due to their ability to maintain mechanical strength and resistance to oxidation at extremely high temperatures. These materials, such as nickel-based, cobalt-based, and iron-based superalloys, are essential for components in jet engines and gas turbines. Here they endure the intense heat and stress of operation. These superalloys are integral to aerospace manufacturing, enabling the production of components that can withstand extreme conditions.

The development of these superalloys has significantly improved the efficiency and performance of modern aircraft engines, enabling higher thrust-to-weight ratios and better fuel efficiency. Ongoing research and advancements in superalloy compositions and manufacturing processes continue to push the boundaries of what is possible in aerospace engineering.

The Revolution of Composite Fabrication

Composite materials have been revolutionary in aerospace innovation. Carbon fibre-reinforced polymers (cfrPs) and other composites offer exceptional strength, stiffness, and corrosion resistance. By incorporating composites into aerospace vehicles, weight reduction is achieved, resulting in improved fuel efficiency, increased payload capacity, and enhanced overall performance. Composites are employed in various components, including wings, fuselage structures, and interior panels, significantly impacting efficiency and durability. The process of composite fabrication is essential for producing these high-performance materials, ensuring they meet the stringent requirements of aerospace applications.

The Quest for Lightweighting

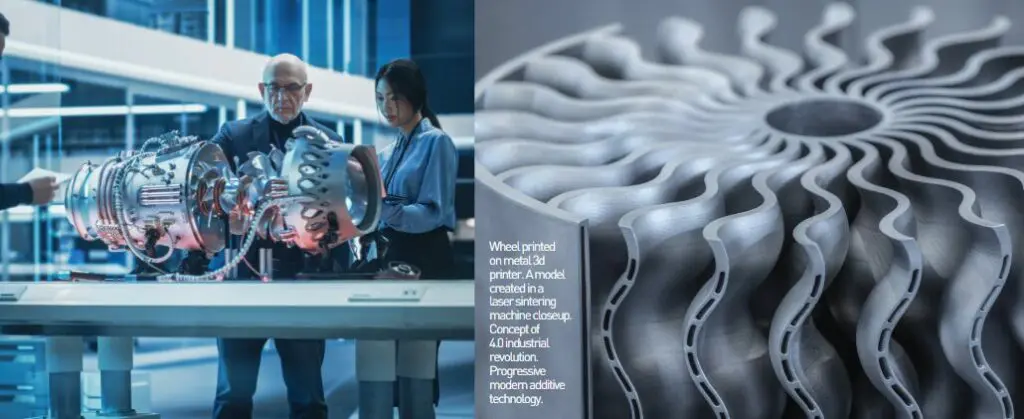

Aerospace design places a premium on lightweighting for greater fuel efficiency, extended range, and reduced environmental impact. Engineers employ innovative design techniques and advanced lightweight alloys, such as aluminium-lithium and magnesium alloys, to reduce weight while maintaining structural integrity. Advanced manufacturing techniques like additive manufacturing (3d printing) allow the creation of intricate and lightweight components, optimising aircraft weight. By reducing the weight of aircraft, these techniques significantly lower fuel consumption, leading to cost savings and reduced environmental impact.

Additive Manufacturing in Aerospace: A Game- Changer in the Evolution of Materials

As one of the key emerging technologies, additive manufacturing is revolutionising the way aerospace components are designed and produced. Additive manufacturing, also known as 3D printing, has emerged as a game-changing technology in aerospace materials and structures. This transformative process allows engineers to create complex geometries and lightweight lattice structures that were previously challenging or impossible to manufacture using traditional methods. The flexibility of additive manufacturing in aerospace streamlines production, reduces waste, and accelerates innovation. It also enables rapid prototyping, facilitating quick and efficient design iterations.

Safety and Structural Integrity

Ensuring the safety and structural integrity of aerospace vehicles are paramount. Rigorous testing, analysis, and certification processes are implemented to validate components’ ability to withstand extreme loads and environmental conditions. The implementation of a digital thread enhances communication and data sharing, ensuring that all stakeholders have access to critical information for maintaining safety and structural integrity.

Non-destructive testing techniques

Non-destructive testing techniques, such as ultrasound, X-ray, and thermography, allow for the inspection of materials and structures without causing damage. These methods enable the detection of internal flaws, material inconsistencies, and potential weaknesses, ensuring the reliability and safety of aerospace components. Additionally, advanced non-destructive testing can provide detailed imaging and real-time monitoring, facilitating the early identification of issues and reducing maintenance costs. Machine learning algorithms are increasingly being used to analyse data from non-destructive testing, improving the accuracy and efficiency of defect detection.

Ongoing research in aerospace innovation

This focuses on developing new aerospace innovation ideas such as:

- Self-healing materials – that can autonomously repair minor damages. These self-healing materials use embedded microcapsules containing healing agents, which are released when damage occurs, filling in cracks and restoring the material’s integrity. The potential applications in aerospace include increasing the lifespan of components and enhancing safety by maintaining structural integrity. Aerospace innovation technology like this could significantly reduce maintenance costs and improve the overall performance of aerospace structures

- Smart structures – integrated with sensors and actuators to monitor the health and performance of aerospace vehicles in real-time, which enhances safety and efficiency. These smart structures detect stress, strain, and potential damage, allowing for predictive maintenance and timely interventions. Additionally, they adapt to changing conditions and optimise performance dynamically, leading to improved fuel efficiency and reduced operational costs

- Artificial intelligence – is at the forefront of aerospace innovation, enabling the development of smarter and more efficient materials and structures

Conclusion: A Journey Towards Flight Excellence

In conclusion, the aerospace industry continues to push the boundaries of what is possible through innovative materials and ingenious structures. From traditional metals to advanced composites, from lightweighting strategies to additive manufacturing, each advancement propels us closer to a future where aircraft and spacecraft are lighter, stronger, and more sustainable than ever before. By harnessing the properties of materials such as carbon fibre composites, titanium alloys, and ceramics, aerospace engineers create vehicles that are fuel-efficient, high-performing, and capable of withstanding extreme environments. The evolution of materials like these is shaping the modern aerospace industry, making it more efficient, sustainable, and innovative.

As we explore the captivating world of aerospace materials and structures, we witness the relentless pursuit of flight excellence. The historical significance of traditional materials merges seamlessly with the transformative power of advanced materials, showcasing the industry’s evolution. Through composite materials, lightweighting strategies, high-temperature materials, additive manufacturing, and a strong emphasis on safety, the aerospace industry propels us towards a future where the boundaries of flight are continually expanded. With each breakthrough, we inch closer to a world where the skies are filled with aircraft and spacecraft that embody the pinnacle of engineering innovation and inspire generations to dream of the possibilities that lie beyond our atmosphere.

Contact information

As we have said aerospace innovation seems to have no boundaries. The evolution of materials needed for tomorrow’s aerospace industry is a driving force behind R&D. DTC will be here along the way, to speak to us about technologies such as self-healing materials and ideas for additive manufacturing in aerospace.

Contact us using these methods:

- Call us – 02380 251 100

- Contact form – https://www.dtc-uk.com/contact/

- Email – sales@dtc-uk.com