Maintaining a reliable supply chain and keeping adequate stock on hand is essential for any production-focused engineering business. Workers need timely access to the tools and materials required to complete their tasks effectively.

Even the slightest chink in the supply chain’s armour can lead to delays that snowball and push projects off schedule.

Maintaining a reliable supply chain and keeping adequate stock on hand is essential for any production-focused engineering business. Workers need timely access to the tools and materials to complete their tasks effectively.

Even the slightest chink in the supply chain’s armour can lead to delays that snowball and push projects off schedule.

One of the most exciting and potentially most profitable is Vendor Managed Inventory (VMI).

Many people have heard of VMI, but few fully understand how it works. In this post, we’ll explore the fundamentals of VMI, including what it is, why you might need it, and whether it is right for your business.

What Is Vendor Managed Inventory?

VMI is a collaborative approach to stock control and supply chain management. The supplier and the customer work together to manage stock replenishment for mutual benefit. When properly implemented, VMI can streamline processes, improve reliability and reduce costs.

In most cases, the supplier assumes full responsibility for managing the customer’s inventory, aiming to maintain agreed minimum stock levels at all times.

Because the supplier is overseeing the customer’s stock, contracts often include terms relating to unsold inventory. This usually takes one of two forms:

The supplier agrees to buy back unsold stock if demand is lower than expected.

The supplier retains ownership of the stock until it is sold, and the customer takes a commission per sale.

Why Is VMI Beneficial for Suppliers?

VMI might seem to benefit customers more than suppliers. After all, suppliers take on more responsibility and risk. So why would they agree to it?

The answer lies in customer loyalty and long-term business.

When a customer has a reliable VMI setup in place, switching suppliers becomes much harder. Implementing VMI takes time, effort and resources. As long as the supplier delivers competitive prices and dependable service, they are likely to retain the customer over the long term.

Additionally, access to real-time customer data enables suppliers to manage their own inventory more effectively. This leads to operational efficiencies and higher profit margins.

With several years of data, VMI systems can forecast demand with remarkable accuracy. This allows suppliers to carry exactly the right amount of stock without overcommitting resources.

How to Ensure VMI Success

As you’ve seen, VMI offers clear advantages, but it does require commitment from both parties. Here are a few tips to increase the likelihood of success:

- Align Expectations Early

Both the customer and the supplier need to be aligned from the outset. Set clear short-term and long-term goals instead of relying on vague commitments. This clarity prevents misunderstandings and reduces the risk of the partnership breaking down.

This is especially important for suppliers, who do most of the work in the early stages before data-driven efficiencies take shape. - Agree on Information Sharing

Establish what information needs to be shared from the start. Customers may hesitate to provide sensitive data, but forecasts and production schedules should be included at a minimum. No reputable supplier will expect proprietary data, but transparency is vital for success. - Communicate Regularly

Teething issues are inevitable. When things go wrong, treat them as opportunities to refine the process rather than place blame.

Most VMI failures stem from communication breakdowns. Both parties should commit to open and ongoing dialogue, especially when circumstances change

Conclusion

Vendor Managed Inventory is not a quick fix. It requires trust, planning and a willingness to collaborate. But for the right customer and supplier, the long-term gains far outweigh the short-term effort.

If you’re ready to reduce stock shortages, improve supplier relationships and streamline your operations, VMI might be the solution you’ve been looking for.

Best Tool to Help: The DTC HUB

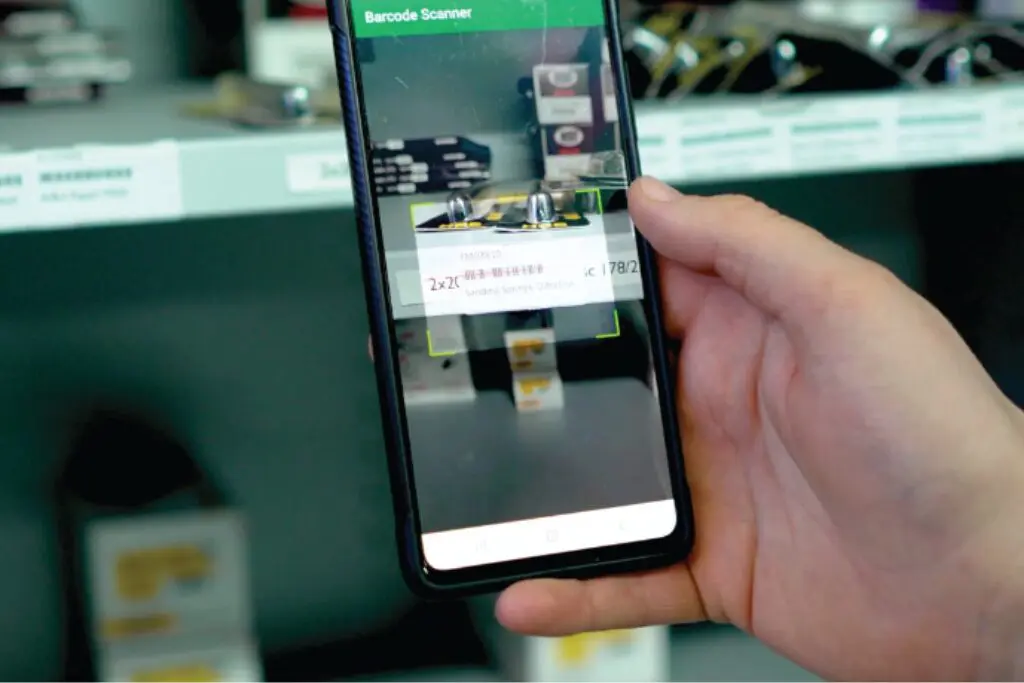

DTC HUB is a digital partner for more innovative stock management and ordering. From real‑time inventory tracking to fast, accurate ordering, our platform ensures that your supply is made simple.

It isn’t just a tool; it’s an extension of your team. Combining advanced digital features with expert support helps you optimise every step of your supply chain.