Which coverall should I use? If you’re deciding which coveralls you or your operators should be using, there are many options available and it’s vital you get it right to ensure the best protection and the most cost-effective solution.

There are a few main factors to consider:

- Reusable vs disposable

- Cost effectiveness

- Material or fabric

- Comfort and fit

- Protection level

Advantages of Disposable Coveralls

Hygiene and Safety

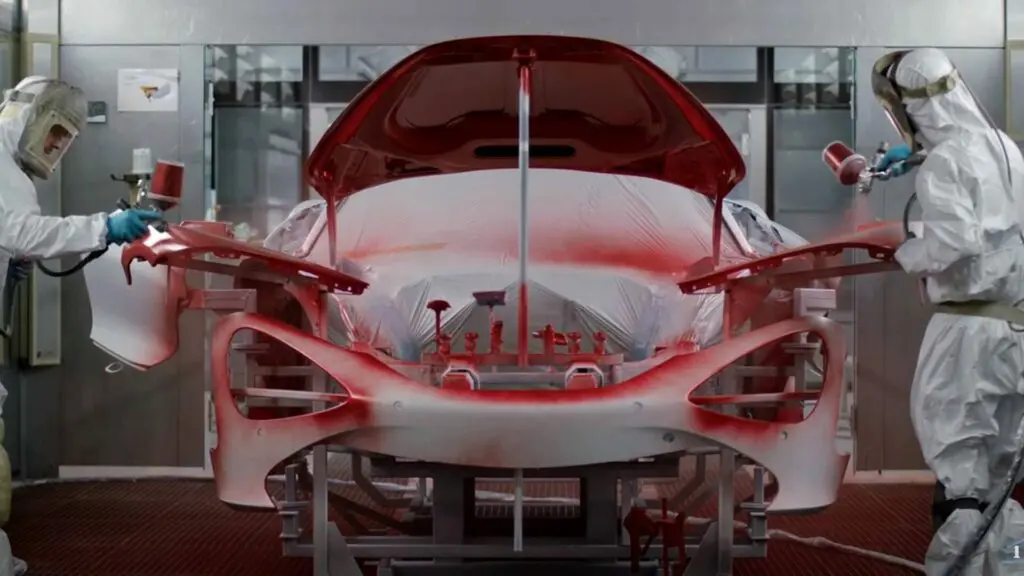

One of the main reasons for using disposable coveralls is that they’re always clean when first used, meaning that it eliminates cross-contamination risks. This is particularly important in paintshops or clean environments where cleanliness is at a premium.

Cost-Effectiveness

Disposable coveralls are cheaper than reusable coveralls initially, and will also save on ongoing laundering, maintenance, and repair costs.

Convenience

There’s no need to store or manage disposable coveralls after use, they can simply be disposed of and replaced. Likewise, if a coverall is soiled and needs replacement, a clean one is always readily available.

Consistent Quality

The quality of the coverall is always the same when using disposable coveralls and offers the same protection straight from the package. There’s no degradation over time like you can get from heavy use or repeated laundering that you can get with reusable coveralls.

Choosing the Right Disposable Coverall

Assess the Job Environment

It’s vital that the right coverall is chosen for the right hazard and protection needs. Make sure that you refer to the product data sheet to ensure that you’re getting the right level of protection.

Coverall Features

When choosing the right coverall, you’ll need to check that the features it offers are relevant to your needs. What are the fabric barrier properties? Is it better for liquids or particulates? Are your operatives using paints and solvents, or doing hazardous dusty work?

It’s also worth considering the environment and time of year the coveralls will be worn. There may be situations where breathability is a key factor to keeping your operators cool.

Think about the cuffs and waists. Are they long cuffs, or short cuffs? Are the zippers double sided? Do you need a hood? All these things shouldn’t be overlooked.

Cost Analysis

It’s worth ensuring you have the right coverall for the job, because is you’ve got a coverall that offers a higher level of protection it will often be more expensive without offering any real benefits.

Consider a Colour Coded Coverall System

The BAXT Coverall system is an example of a colour-coded system that makes it easy to spot whether an operator is wearing the correct level of protection at a glance.

Red – Prepper

The red “prepper” coverall has the lowest level of protection and is designed for doing dusty work which doesn’t need a high level of liquid protection. Ideal for doing dusty prep or sanding work.

Orange – Laminator

The orange “laminator” coverall has a high level of liquid protection as well as dust protection and has a large breathable back to ensure operator comfort. It’s idea for operators in the laminating section of the composites industry where they’re exposed to a wide range of hazards.

Green – Painter

The green “painter” coverall has the highest level of protection and is designed for those working with paints, solvents, and liquid chemicals.

BAXT Coveralls Video

Here’s an overview of the BAXT Coveralls colour coding system:

Advantages of Reusable Coveralls

Long-term Cost Savings

Although reusable coveralls are more expensive upfront, they can be more cost-effective over the long term, particularly if you have a large workforce.

It’s worth considering though, the costs of laundering, repairs, and eventual replacement.

Durability and Strength

Reusable coveralls are made from stronger materials and will withstand many uses and are more suited to environments that are less subject to chemicals and contamination and more susceptible to physical damage.

Don’t forget through that reusable coveralls can suffer from decreased effectiveness over time.

Environmental Impact

Reusable coveralls generate less waste compared to disposable coveralls and can be more environmentally friendly if managed with proper laundering systems.

Make sure you factor in the environmental and monetary cost of water, detergents and energy needed to keep them clean. Likewise, when a coverall reaches the end of its life it must still be discarded.

Comfort and Customisation

Reusable coveralls can be designed for better comfort with features like pockets, reinforced seams, and additional padding, a well as customised fit for individual operators.

The Takeaway: Which Coverall Should I Use?

Which Coverall Should I use? Disposable Coveralls

Disposable coveralls are an excellent choice for the aerospace, automotive, marine and composites industries due to their superior hygiene, cost-effectiveness, and convenience. Because they’re single use, it eliminates the risk of cross-contamination in clean environments. With no need for ongoing laundering, maintenance, or storage, they offer excellent protection combined with operation efficiency.

Which Coverall Should I use? Reusable Coveralls

Reusable coveralls can be a viable option due to their durability and potential for long-term cost savings, particularly if you have an exceptionally large workforce. While the initial investment is higher, savings can be made over the long term if you partner with the right laundry company.

It’s worth considering though, the costs of laundering, repairs, and eventual replacement.

-

3M Disposable Protective Coveralls 4530£7.18 Incl. VAT£5.98 Excl. VAT

3M Disposable Protective Coveralls 4530£7.18 Incl. VAT£5.98 Excl. VAT -

3M Protective Coverall 4535£7.18 Incl. VAT£5.98 Excl. VAT

3M Protective Coverall 4535£7.18 Incl. VAT£5.98 Excl. VAT -

BAXT C7 Disposable Coverall (PAINTER)£7.14 Incl. VAT£5.95 Excl. VAT

BAXT C7 Disposable Coverall (PAINTER)£7.14 Incl. VAT£5.95 Excl. VAT -

BAXT C5 Disposable Coverall (LAMINATOR)From £7.14 Incl. VATFrom £5.95 Excl. VAT

BAXT C5 Disposable Coverall (LAMINATOR)From £7.14 Incl. VATFrom £5.95 Excl. VAT -

BAXT C3 Disposable Coverall (PREPPER)£5.94 Incl. VAT£4.95 Excl. VAT

BAXT C3 Disposable Coverall (PREPPER)£5.94 Incl. VAT£4.95 Excl. VAT -

BAXT Racetec R7 Premium Painters Coverall£116.06 Incl. VAT£96.72 Excl. VAT

BAXT Racetec R7 Premium Painters Coverall£116.06 Incl. VAT£96.72 Excl. VAT