Selecting the best abrasives for fairing boats is a crucial part of the boat building and boat maintenance process. It’s not just cosmetic though, it can have a massive impact on the performance and efficiency of the finished vessel.

The choice of abrasives used in the fairing process is vital for smoothing and shaping the hull in the most effective and quickest way, as well as ensuring the most long-lasting finish.

Understanding Boat Fairing

Boat fairing is the critical step in making and maintaining boats where the hull is filled, shaped and smoothed to ensure optimal performance and the best possible aesthetic finish. This process addresses imperfections that can occur during the manufacturing process (if there are imperfections or defects in the mould) or defects that occur during the working life of the boat.

In its simplest form, fairing starts with applying filling compounds to the hull to remove any structural inconsistencies. It’s important that the correct compounds are chosen based on their compatibility with the hull material and the specific requirements of the boat.

The Best Sanding Tools and Abrasives used for Fairing Boats

Depending on the part of the process, the choice of sanding tool and abrasive has a massive impact on the time taken and the finished results.

Belt Sanders

Belt sanders are a great way to remove bulk material at a high speed and are also very effective for removing gel coats if required. Sanding belts are available in grits as coarse as P40 and are highly effective at rapid material removal.

The Best Abrasives for use with Belt Sanders when Fairing Boats

Cloth Sanding Belts offer excellent stock removal and are available in various coarse grits.

Finger Files

Finger files are belt sanders with very narrow belts (as narrow as 10mm) and are great for getting into very tight spaces that regular belt sanders can’t reach. Sanding belts for finger files are also available in grits as coarse as P40.

The Best Abrasives for use with Finger Files

Finger File Sanding Belts come in widths ranging from 10mm to 20mm, and belts made with a zirconia grain and cloth back will last longer and cut faster.

Grinders

Grinders are great for shaping and for areas where the belt sander is too big, and a finger file is too small. Grinders with dust extraction reduce dust and increase operator safety.

The Best Abrasives for Use with Grinders for Fairing Boats

Fibre Abrasive Discs are cost effective, long lasting and heat resistant.

Ceramic Fibre Abrasive Discs offer all the benefits of regular discs but with added speed and longevity.

Flap Discs give unrivalled speed but are more expensive than standard discs.

Fairing Boards & Long Sanding Pads

This is where things get a little bit more specialist and depends on the specific requirement or stage of the fairing process:

Hard Hand Sanding Boards for Fairing Boats

For shaping by hand, Hard Hand Sanding Boards produce a true flat surface. Use with Velcro sandpaper. Also available with extraction for a dust free experience.

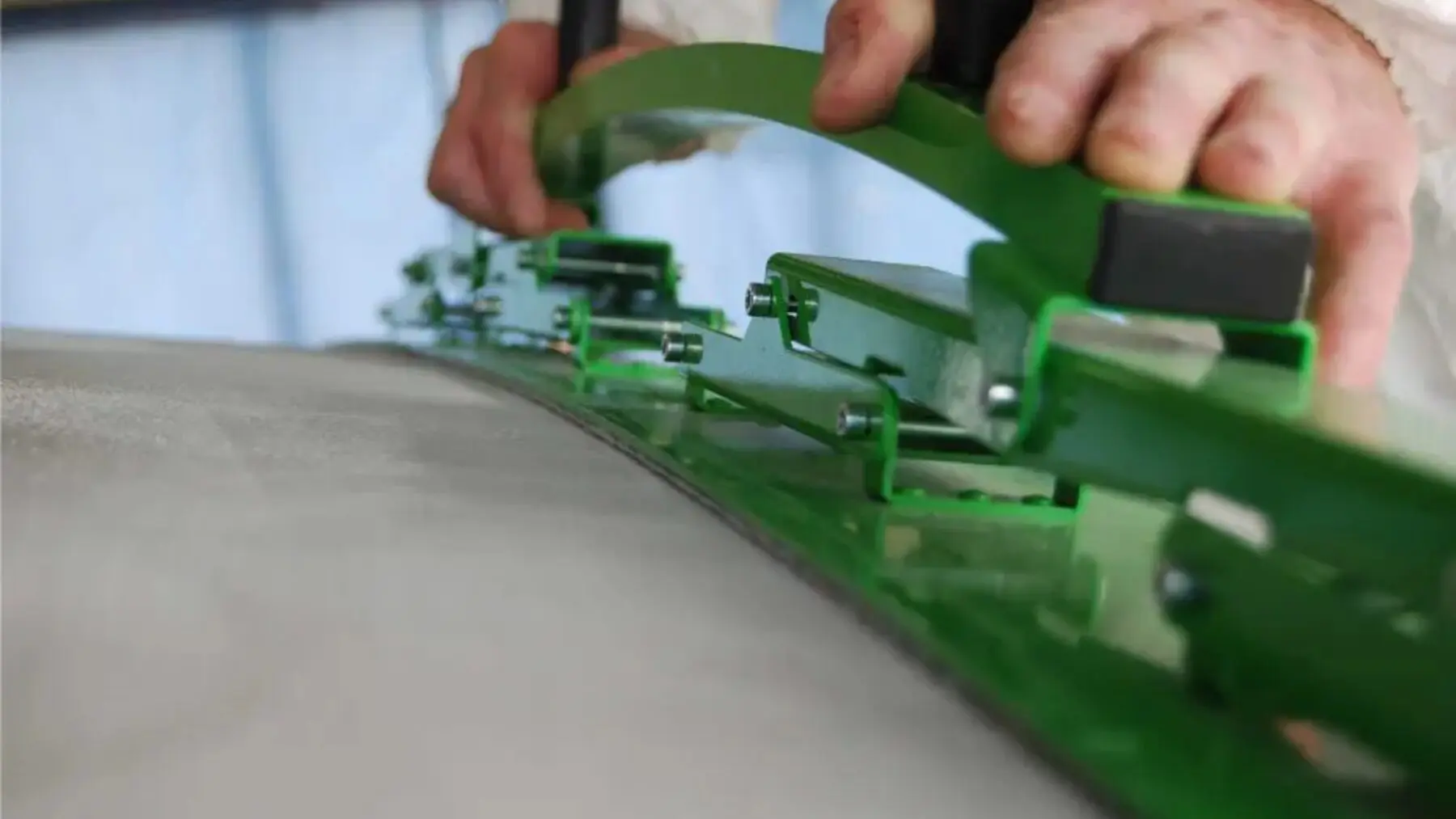

Flexible Sanding Boards

Available in a range of sizes up to almost two metres in length, Flexible Sanding Boards curve to the shape of the surface being sanded and are great for finer shaping.

Flexible Sanding Boards with extraction

An upgrade to the flexible sanding boards, they can be connected to extraction and used with a net-style abrasive for maximum cleanliness and operator safety.

The Best Abrasives for use with Fairing Boards and Long Sanding Pads

Velcro Abrasive Rolls offer the best value for money and are easy to cut to length to suit the board size.

CARBONite Velcro Abrasive Rolls have a blend of ceramic and aluminium oxide grains which are “self-sharpening” for a long life and less frequent changes.

Mirka Abranet Abrasive Rolls are made of a mesh “net” abrasive for maximum dust extraction and minimal clogging.

Long Bed Orbital Sanders

Long bed orbital sanders are ideal for large, flat surfaces requiring the smoothest surface. Available in electric or pneumatic versions.

The Best Abrasives for Use with Long Bed Orbital Sanders

Standard Abrasive Rolls can be cut to size easily and are good for sanders without a Velcro backing pad.

For Velcro backing pads, Velcro Abrasive Rolls offer excellent value for money and are easy to cut to length to suit the backing pad size.

CARBONite Velcro Abrasive Rolls have a blend of ceramic and aluminium oxide grains which are “self-sharpening” for a long life and less frequent changes.

Pre-cut Sanding Strips offer ultimate convenience when paired with the relevant backing pad size.

Mirka Abranet Abrasive Rolls are made of a mesh “net” abrasive for maximum dust extraction and minimal clogging.

Orbital Disc Sanders

For fairing boats, orbital sanders are used for finer finishing work when the initial smoothing and shaping has been completed, and for between coats of primer and topcoat.

Available in many different models, including pneumatic and electric.

The Best Abrasive Discs for use with Orbital Disc Sanders

Velcro Sanding Discs are a great cost-effective option and good for sanding with minimal clogging.

BAXT D6 Latex-backed sanding discs offer greater flexibility and with a unique combination of sanding grit, material bonding, and surface technology to minimise clogging, the D6 lasted 30% longer than comparable products under intensive testing.

BAXT AeroNET discs are constructed of a unique Velcro-backed mesh for the very best dust extraction. The design provides minimal clogging and pilling, and best of all, they are designed to have the longest lifespan possible. It reduces edge wear and is versatile enough to suit a variety of applications.

Smirdex 750 Ceramic Net Velour discs offer speed and irrefutable sanding efficiency with best-in-class dust extraction ability.

BAXT CARBONite Sanding Discs are constructed with with the NANO ZrlO blend of Zirconium, Aluminium Oxide and Ceramic grains for the fastest and longest-lasting abrasive product we have ever tested.

BAXT Crystal Cut Abrasive Discs are high-grit discs on a very flexible back for sanding down prior to the final coat of paint.

Dust Extractors for Sanding

Not to be overlooked, dust extractors are a vital part of the sanding process and can be connected to almost all of the sanding tools we’ve listed and greatly increase the quality of the working environment and operator safety.

The final cut

Selecting the best sanding tools and abrasives for fairing boats is a nuanced decision, influenced by a myriad of factors including the size and construction of the boat, the specific fairing needs, and the desired finish. We’ve explored the various options available, from hand sanding tools and electric sanders to a range of abrasive materials, each with its unique benefits and applications. It’s clear that making the right choice can significantly impact the efficiency of the fairing process and the quality of the final outcome.

When making an informed decision, there are some important questions to ask:

- What is the size of the area to be faired? Larger areas might benefit from powerful electric sanders, while smaller or more intricate areas might require the precision of hand sanding.

- What is the condition of the boat’s surface? Different levels of surface imperfection require different grits or abrasives.

- What finish is desired? The choice and method of sanding makes a big difference to the quality of the finish.

- How much time and budget are available for the project? Some tools and abrasives may be more cost-effective but require more time, and vice versa.

- How important is dust management? Depending on the working environment, tools with dust extraction capabilities might be preferred to maintain a clean workspace and reduce health risks.

Choosing the best tools and abrasives for boat fairing is not a one-size-fits-all scenario. But by considering these questions you can tailor your approach to meet your specific needs, ensuring a high-quality finish that protects and enhances your boat’s appearance.