Hydrogen Power: The Sophisticated Case for Clean Energy

As global decarbonisation efforts accelerate, hydrogen is emerging as a critical element in the energy transition but its path to wide adoption is more nuanced than many realise.

Beyond “Clean” Energy: The Production Spectrum

Not all hydrogen is created equal. While touted as a zero-emission fuel, over 95% of today’s hydrogen is “grey” produced from natural gas, emitting 9-12kg of CO₂ per kilogram of hydrogen. “Blue” hydrogen incorporates carbon capture to reduce emissions by 60-90%, while truly carbon-neutral “green” hydrogen produced via renewable-powered electrolysis represents less than 2% of current production.

The economics remain challenging: green hydrogen costs £3.5-5/kg versus £1.3-2.1/kg for conventional production. Projections suggest a 40-60% cost reduction by 2030 as electrolysis technology scales and renewable electricity prices continue to fall.

The Technical Reality of Storage and Transport

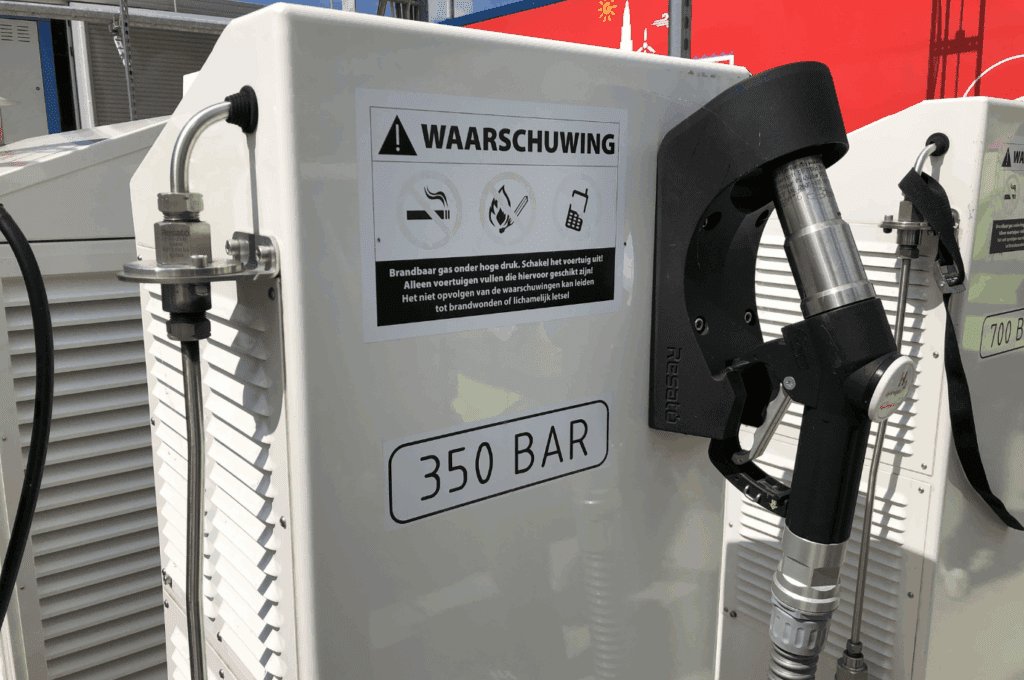

Hydrogen’s physical properties present significant engineering challenges. With exceptional gravimetric energy density (120 MJ/kg) but poor volumetric density (0.01 MJ/L at ambient conditions), hydrogen requires either high-pressure compression (350-700 bar), energy-intensive liquefaction (-253°C), or chemical carriers for practical storage and transport.

These processes impose energy penalties of 10-30% and demand specialised materials to prevent hydrogen embrittlement of conventional metal infrastructure issues often underrepresented in popular discourse around hydrogen adoption.

Sectoral Applications: Where Hydrogen Excels

For heavy transport, hydrogen fuel cells operate at 60% efficiency, substantially outperforming internal combustion engines (25-35%). Hydrogen systems offer compelling advantages for commercial applications:

- System-level energy density of 1.6-2.0 kWh/kg versus 0.1-0.16 kWh/kg for lithium-ion batteries

- Refuelling times of 10-15 minutes compared to hours for equivalent battery charging

- Minimal payload reduction (5-7%) versus battery alternatives (15-25%)

In power generation, hydrogen enables grid-scale seasonal storage capabilities that surpass battery limitations, while achieving electrical efficiencies of 55-60% in advanced turbine systems. For aviation, hydrogen offers two pathways: direct combustion in modified turbines or fuel cell electric propulsion with system efficiencies of 40-45%, though volumetric constraints currently limit applications to smaller aircraft and shorter routes.

The Infrastructure Challenge

Global hydrogen infrastructure remains nascent, with fewer than 700 refuelling stations worldwide. Distribution approaches include repurposing 70-85% of existing natural gas pipelines at 10-30% of new-build costs and developing liquefaction facilities at £500-750 million per GW of throughput capacity.

The economic viability of these investments hinges on effective carbon pricing. Analysts suggest prices of £42-58/tonne would enable blue hydrogen cost parity, while green hydrogen requires £83-100/tonne under current production economics.

Strategic Integration, Not Silver Bullets

As hydrogen technologies mature, their integration with complementary clean energy systems not competition, will determine their role in decarbonisation. Industrial clusters, where hydrogen production, storage, and multiple applications can share infrastructure, present the most promising near-term deployment model.

The technology’s most significant potential lies not in complete energy system dominance, but in strategically addressing sectors where direct electrification proves technically challenging or prohibitively expensive. With continued innovation in production efficiency, storage solutions, and regulatory frameworks, hydrogen will likely emerge as an essential, if specialised, component in the complex mosaic of tomorrow’s low-carbon economy.