Tool Lifetime - what impacts it and how to extend it

In busy production environments, tool wear is often treated as an inevitable part of the job. But tool life is influenced by much more than just frequency of use. Storage conditions, operator habits, working environment and consumable selection all play essential roles in determining how long your tools perform at their best.

Understanding these factors can help reduce premature wear, improve safety and save money across the business. Here we take a closer look at the most common causes of tool degradation and what you can do to prevent them.

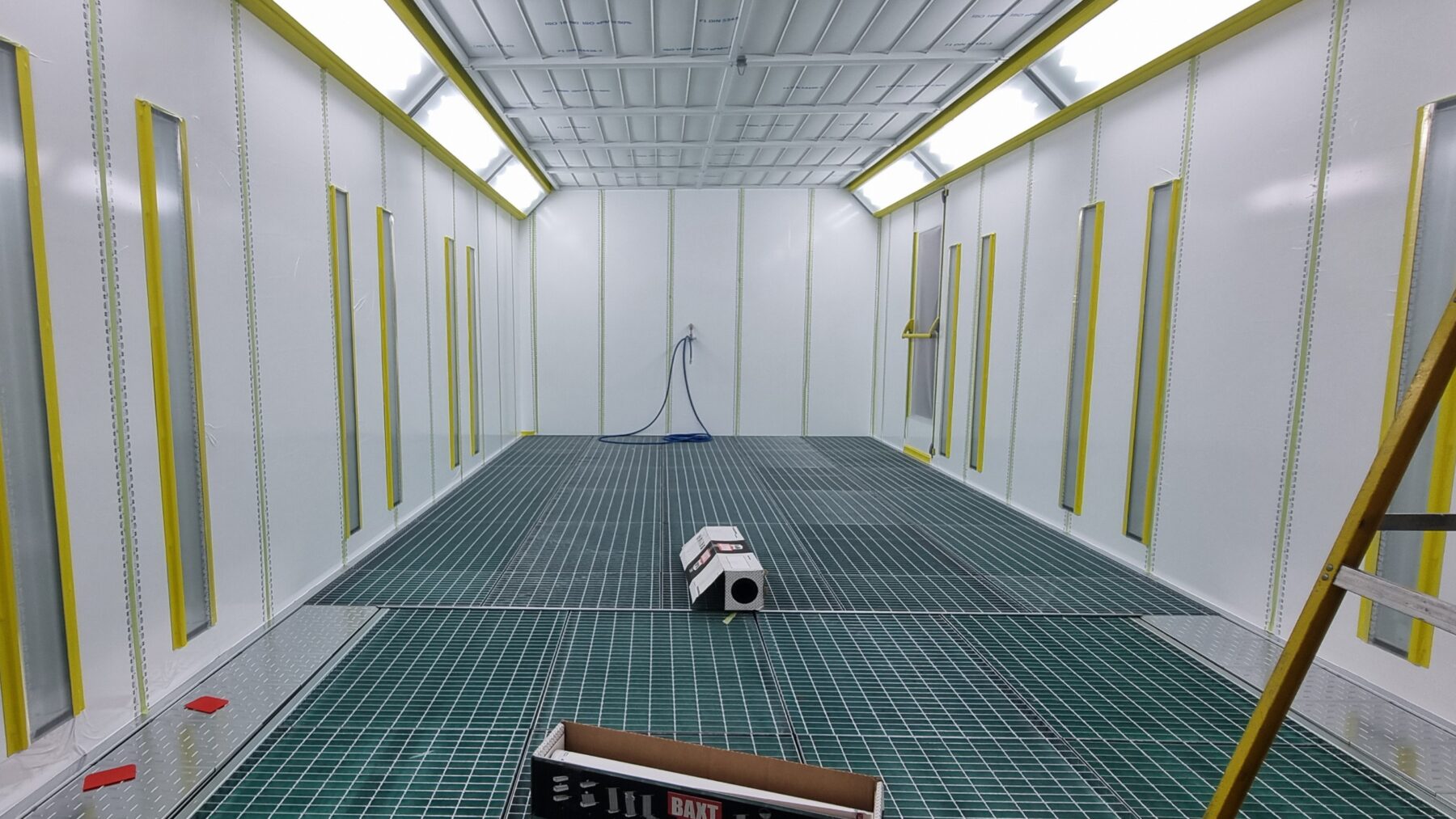

Improper storage

Tool care begins before use. Storing tools in damp or cluttered spaces can lead to rust, damage or reduced accuracy over time. This is particularly critical for precision instruments. Introducing organised storage systems, clean workstations, and controlled environments can dramatically extend tool life.

Environmental conditions

Tools are affected by the air around them. Fluctuations in temperature, high levels of dust or humidity, and exposure to chemicals can lead to corrosion, distortion or general wear. For sectors such as marine, composites and aerospace, managing environmental exposure is vital for tool longevity.

Operator habits

Even the best tools will wear quickly if used incorrectly. Excessive force, poor handling and skipping maintenance are all common causes of damage. Training staff to follow best practices and encouraging a culture of care can make a significant difference to tool lifespan and performance.

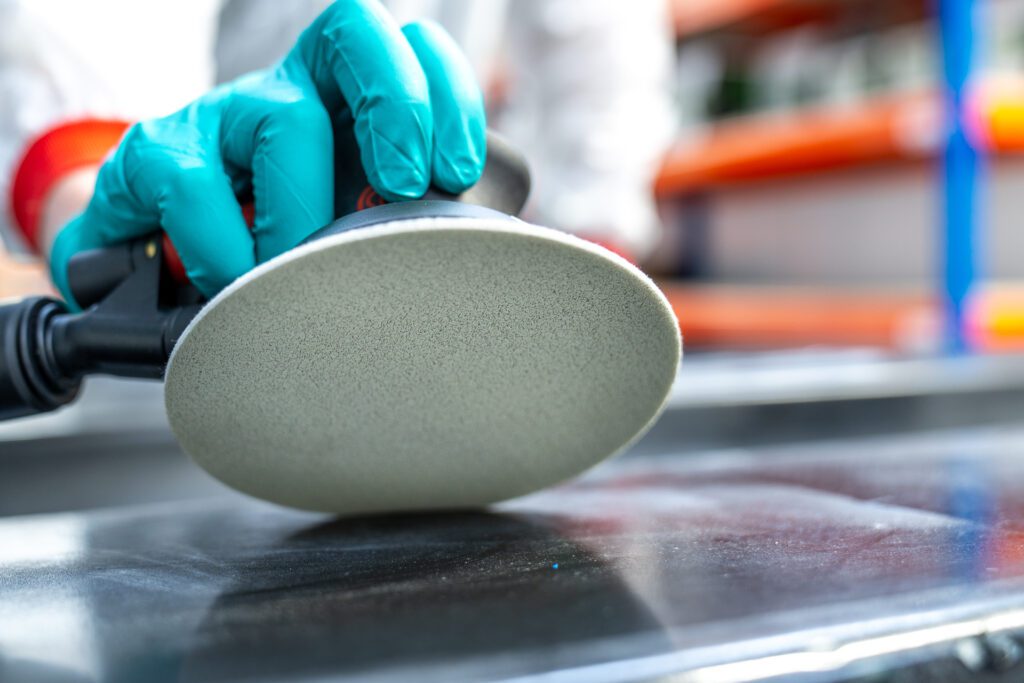

Consumable compatibility

Using the wrong consumables can accelerate tool wear. For example, an overly abrasive disc or unsuitable cutting fluid can cause unnecessary strain. Always pair tools with the right accessories for the material, process and application to reduce friction, heat buildup, and wear.

Lack of maintenance routines

Neglecting simple maintenance can shorten the life of even the most robust tools. Regular cleaning, checking for damage and replacing worn parts all contribute to longevity. Implementing routine inspections ensures tools remain safe, sharp and reliable.

A smarter approach to tooling

Tool life is not just about how often a tool is used. It is about how it is stored, handled, maintained and supported. Paying attention to the details at every stage of a tool’s life cycle helps avoid costly breakdowns and ensures consistently high performance.

By focusing on these often overlooked factors, workshops can protect their investment and raise their standards.