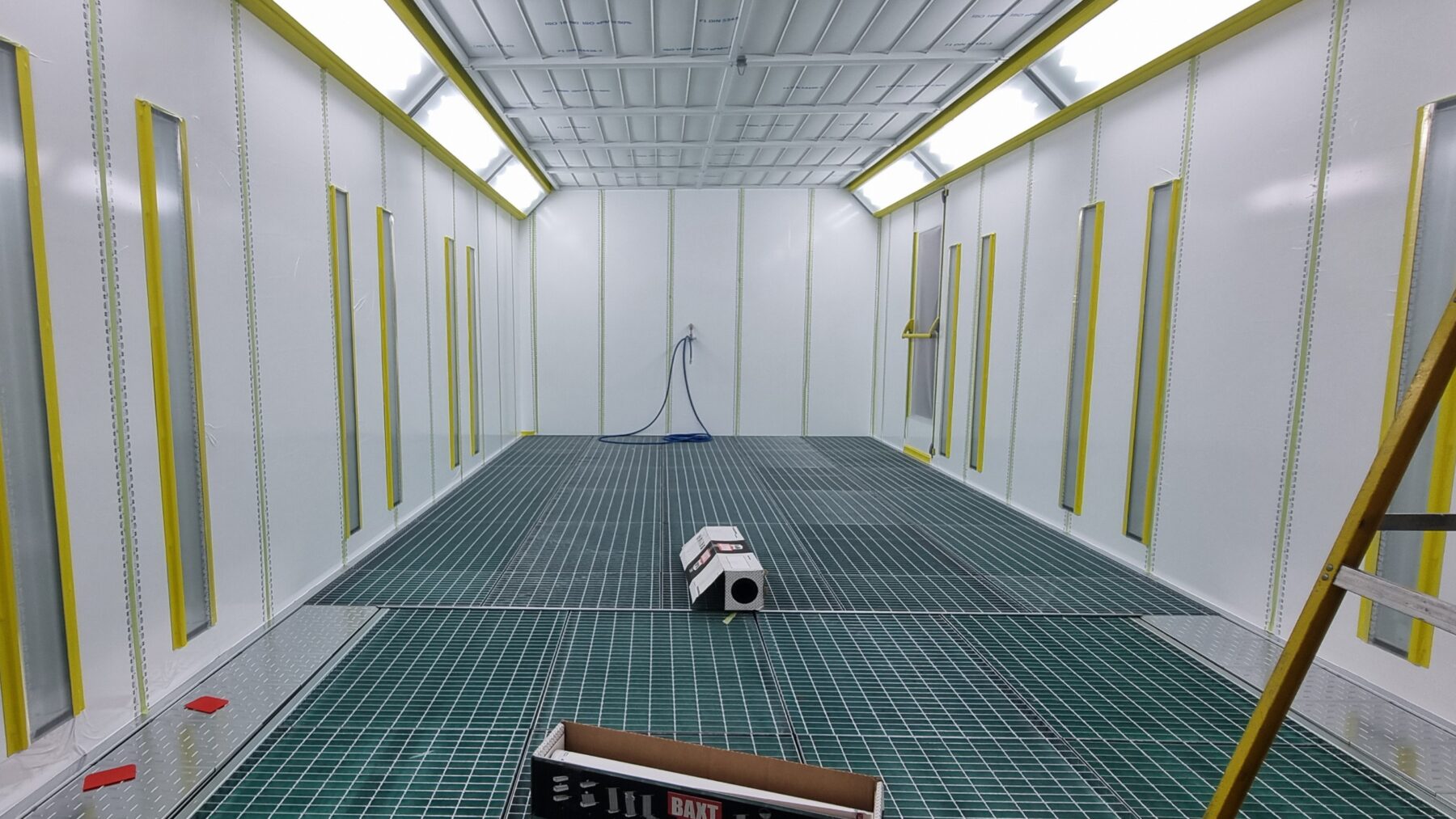

What’s really in the air in a paintshop?

Walk into a paintshop and the risks feel obvious. The sharp, familiar smell of solvents such as polyurethanes, epoxies, and other coatings hangs in the air, alongside wet paint, spray equipment, and the constant movement of jobs in and out of the booth.

What often gets overlooked is the part you cannot see.

Every time paint is sprayed, sanded, mixed, or cleaned down, the air changes. Fine particles, vapours, and aerosols are released and can remain suspended long after the job looks finished. Even with effective extraction, contaminants do not disappear the moment the spray gun is put down.

In most workshops, exposure is not about one dramatic incident. It is about small amounts, day after day.

The air changes with the task

One of the most common mistakes in workshops is treating respiratory protection as a one-time decision. In reality, the risk profile changes depending on the task being carried out.

Spraying, sanding, mixing, flash-off, drying, and clean-down all introduce different contaminants into the air. Protection that is suitable for one stage may be inappropriate for the next.

Understanding what is actually present in the air at each stage is the first step towards choosing the right level of protection.

Particulates: dust, mist, and overspray

Sanding fillers, primers, topcoats, GRP, or carbon fibre generates very fine dust. Spray painting also produces paint mist and overspray that can linger and later become airborne again when disturbed.

These particles are small enough to be inhaled deep into the lungs, particularly during preparation and finishing work. Because they are often invisible, it is easy to underestimate how much is being breathed in.

Where particulates are the primary hazard, respiratory protection needs to be designed to filter solid and liquid particles. This is where particulate-rated protection is required.

For example, during general prep and sanding work, a particulate respirator designed for fine dust may be appropriate, such as a fold-flat FFP2-rated mask.

For higher-risk particulate tasks involving very fine or hazardous dust, a higher protection class may be required. In these cases, an FFP3 particulate respirator is commonly specified following a risk assessment.

Gases and vapours: the risk you stop noticing

Paint and solvent vapours are often strongest during application, but exposure does not end there. Vapours can still be present during flash-off, drying, booth clearing, and gun cleaning.

One of the biggest challenges is familiarity. Over time, people become used to the smell. When the odour fades, it is easy to assume the risk has gone away. In reality, lower-level exposure can continue even when vapours are no longer obvious.

This is where many safety conversations fall short. Disposable particulate masks are designed to filter particles, not gases or vapours. If vapours are present, a particulate-only mask is simply the wrong tool for the job.

For tasks involving solvents, thinners, or chemical cleaning, respiratory protection needs to address vapours, sometimes in combination with particulates, depending on the activity.

For example, a reusable half mask fitted with appropriate vapour and particulate filters may be suitable for tasks such as mixing, gun cleaning, or solvent wipe-downs. Systems with interchangeable filters allow protection to be matched to the specific hazard identified in the risk assessment.

Aerosols: when hazards overlap

Spray processes often create a combination of hazards. Fine droplets, vapours, and solid particles can all be present simultaneously.

For this reason, respiratory protection decisions should not be based solely on the product being used, but on how it is applied and what happens before and after spraying. Removing protection too early, or lifting a visor during clearing or clean-down, can result in unnecessary exposure.

Composite environments bring additional challenges

Composite preparation areas introduce another layer of risk. Sanding carbon fibre or GRP produces extremely fine dust that can linger in the air and settle on surrounding surfaces.

Once disturbed, this dust readily becomes airborne again. Over time, repeated low-level exposure can contribute to respiratory irritation and longer-term health effects.

In these environments, consistent use of appropriate particulate protection during preparation and finishing work is just as important as protection during paint application.

The everyday exposure problem

The danger in a paintshop is rarely dramatic. It is routine. Small, repeated exposures during normal work add up over time.

When people work in the same environment every day, their senses adapt. Warning signs fade into the background. The risk feels lower than it actually is.

This is why protection should be based on the task and the hazard present, not on habit or comfort alone.

Two things that make any mask effective or ineffective

Fit and seal

Even the correct type of mask will not protect properly if it does not fit the wearer. Face seal, strap adjustment, and compatibility with facial hair all matter. A poor fit significantly reduces protection.

Condition and use

Disposable masks are designed for limited use. Filters become saturated. Masks become contaminated. Reusing a mask stored in a dusty environment reduces its effectiveness.

Respiratory protection only works when it is worn correctly, stored properly, and replaced at the right time.

The takeaway

Good protection starts with understanding what is actually in the air.

Ask simple questions:

- Is this a dust hazard, a vapour hazard, or both?

- What stage of the process am I in?

- Has the hazard changed since the last task?

Once the hazard is clear, identifying the right type of protection becomes much easier.

Just because something cannot be seen does not mean it is not there.