Renovating a Spray booth for a premier refinisher of prestige & performance cars

Spray Booth Renovation and Upgrade

Challenges

Solutions

Results

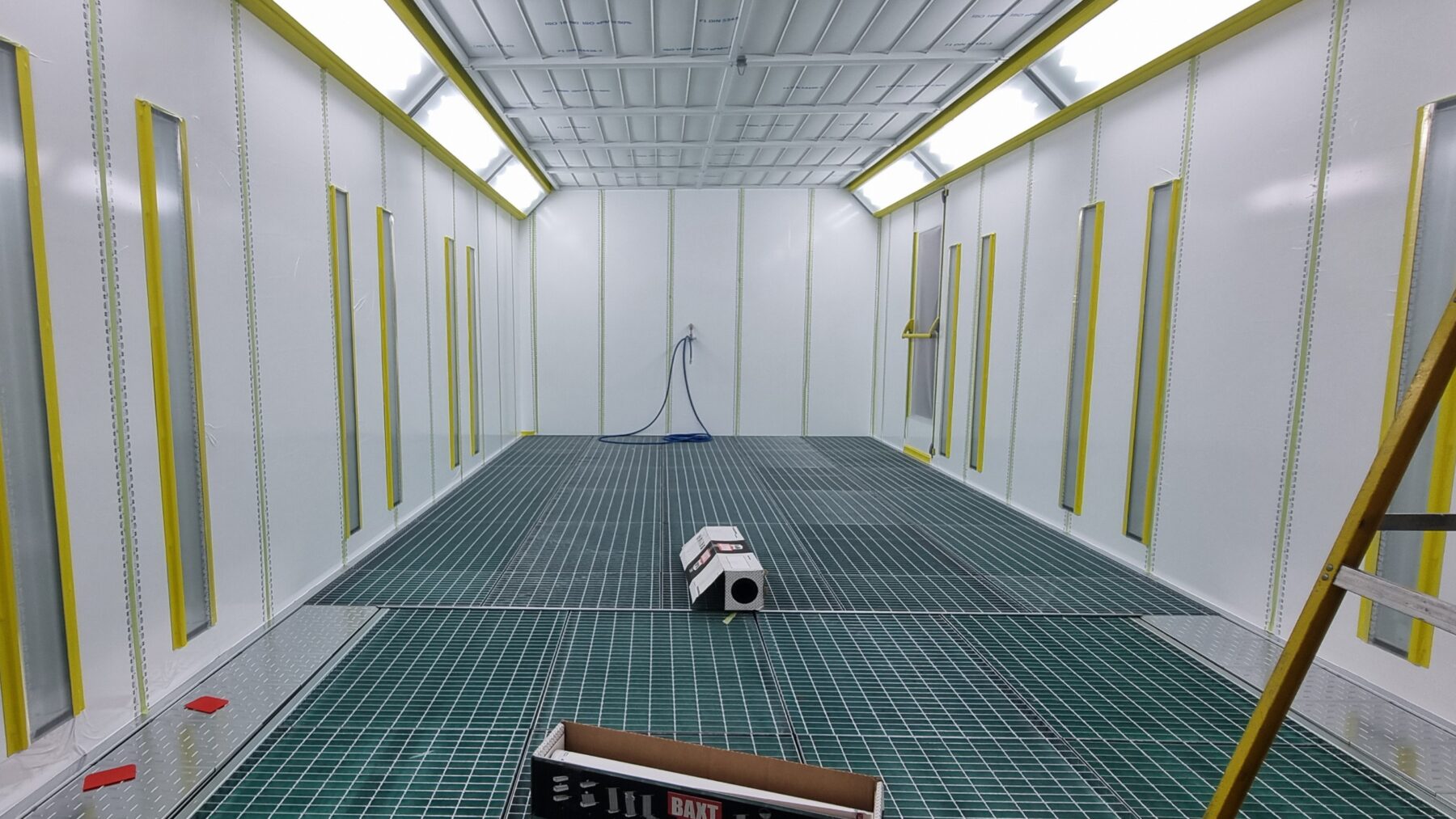

A long-established company specialising in refinishing prestige cars and performance vehicles had an urgent need for a complete renovation of their spray booth due to overspray and paint defects.

After consulting with our experts, they chose to trial the BAXT WP10 product, to test if the self-adhesive film would prove easier to install than their current product.

As well as proving to be strong and durable, the multiple layers enabled much faster renovations of the booth between jobs, maximising production and minimising downtime.

The Overspray Problem

The finishers were experiencing quality issues when their existing dirt trap booth coating film was getting torn and not adhering to the booth walls correctly. This was causing overspray to contaminate the booth and was causing defects in the paint work leading to costly rework.

In addition, it proved to be challenging to cover irregularly shaped areas. Plus maintenance was also proving to take too long and wasn’t easy to fit into their busy production schedule, meaning it was often left a lot longer than it should have been.

An effective and future-proof solution

After consulting with our experts, the customer decided to trial the BAXT WP10 as they hoped the self-adhesive film would prove easier to install, and the 5 layers would enable much faster renovations of the booth between jobs.

They purchased and installed the BAXT WP10 Booth Coating which was “easier to install than we thought it was going to be” and proved to be “more effective and easier to use” than the product they used to use.

Uninterrupted finishing

The result was a very clean and bright working environment through a seamless upgrade to the BAXT WP10 Booth Coating.

Renovating the booth between jobs is now a swift and easy process and they simply peel off the top layer and dispose of the dirty film. The numbered layers make it easy to schedule the full replacement of the film when the last layer is finished.

In addition, the overspray issues have been solved, eliminating the costly rework and interruptions to their schedule.

“We found the BAXT WP10 easier to install than we thought it was going to be – it went up very well and looked the part. When the booth starts to look a bit tired and we pull the top layer off, it makes us smile every time. We were using 3M Dirt Trap before, and this is easier to use, and more effective.”

– Company Director

BAXT LAYERSHIELD WP10 5-Layer Spray Booth Wall Protector

The Baxt LAYERSHIELD WP10 5-Layer Spraybooth Protection Film is a unique product designed to fully protect spraybooth interior walls from dust, dirt and overspray. It is self-adhesive and does not require tape or magnets to secure in place. The statically charged, tacky surface attracts paint overspray away from the operating area and the film provides a bright white workspace, idea for highlighting imperfections and improving quality control. WP10’s insulating properties help to reduce booth heat loss which in turn reduces cost. The layered design means a layer can be easily and rapidly removed, providing a fast refresh with each of the 5 layers.

- INCREASE PRODUCTIVITY: Increase spray booth productivity time by reducing cleaning and maintenance.

- INCREASE QUALITY: Improve your throughput and reduce re-work by maintaining a clean working environment.

- INCREASE PROTECTION: Protect your spray booth and keep this valuable asset in top working order.

- INCREASE MORALE: Boost employee morale and productivity by providing a bright and clean work area.

Contact Us

"*" indicates required fields