Paintshop Article

The Shift to Water-Based Coatings in Paintshops

Paintshops are facing a period of change as water-based coatings steadily replace solvent-based paints. Growing environmental regulations and heightened awareness of worker health have accelerated this shift, pushing industries to adopt cleaner and safer alternatives. For many, the move is more than compliance; it is an opportunity to rethink long-established practices.

Water-based coatings offer clear environmental benefits, significantly reducing volatile organic compound emissions that have long been a concern in both production and finishing environments. They also improve air quality within workshops, thereby lowering health risks for operators who spend long hours near paints and sprays.

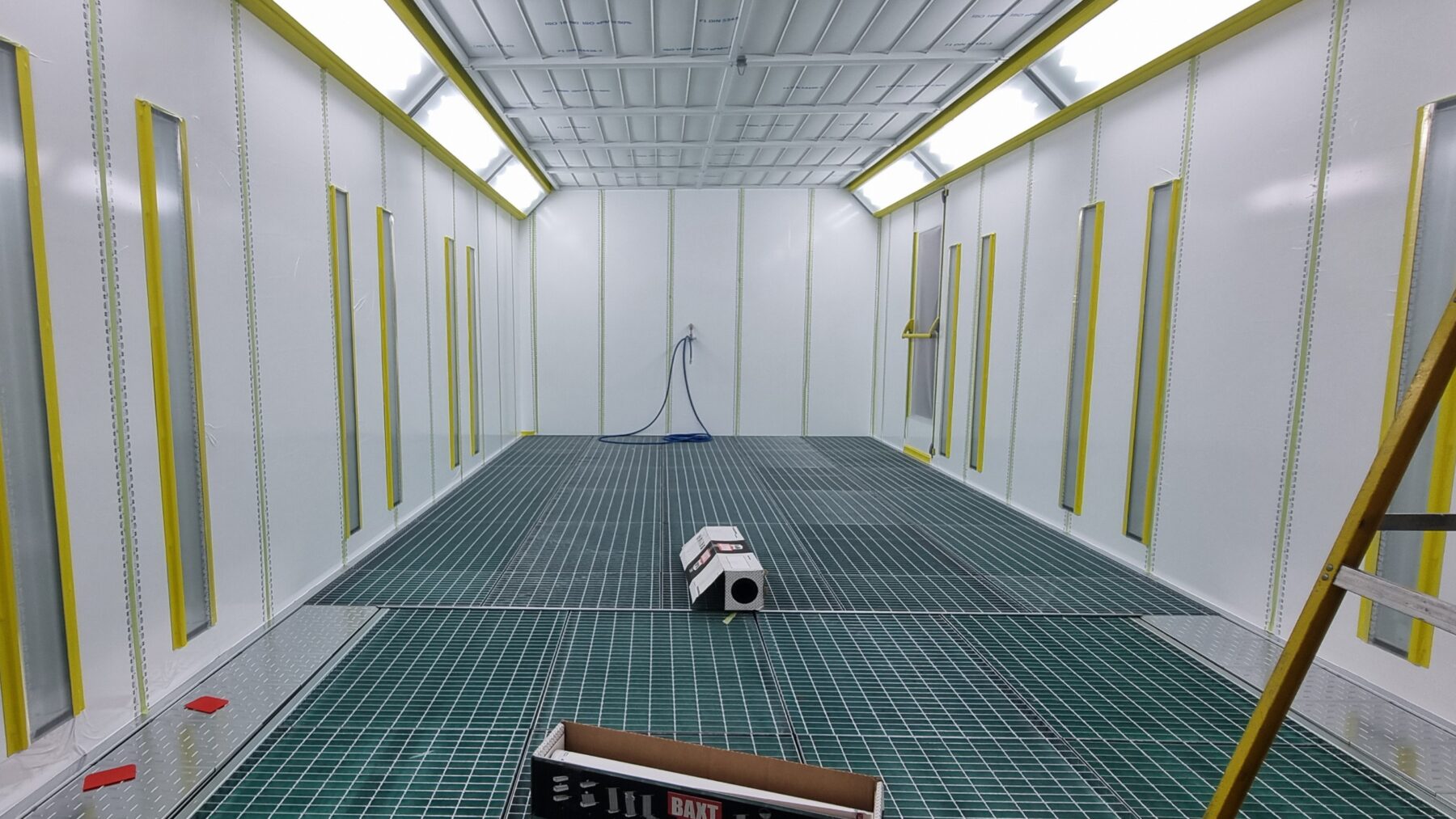

Yet the transition is not without its challenges. Solvent-based paints have been the standard for decades, prized for their reliability, durability and ease of use in demanding environments. Water-based coatings often require different handling techniques, longer drying times and more controlled conditions. Paintshops have had to adapt equipment, retrain staff and refine processes to ensure quality remains uncompromised.

These adjustments are already paying dividends. As more companies invest in advanced spray technologies, controlled curing environments and operator training, the performance gap between solvent and water-based systems continues to close. In some cases, water-based coatings now outperform traditional methods, offering smoother finishes and improved consistency.

For paintshops, this evolution is not just about meeting regulatory demands. It represents a broader commitment to sustainable practices that also enhance long-term efficiency and competitiveness. Those willing to adapt are discovering that water-based systems can deliver both environmental responsibility and high-quality results, thereby securing their place in the future of industrial finishing.